- + Wet-Thermal-wet

- + Plasma-Wet

- + Burn-wet

- + Thermal-Wet

- + Thermal-Dry(Catalyst)

- + Thermal- Dry -PCW

- + Burn-Dry

- + Wet-Burn-Wet

- + Dry Scrubber

- + Wet Thermal PFC Catalyst

- + PFC Catalyst

- + NH3 Catalyst(DeNOx)

- + 氨重組器 Ammonia Reformer

- + 餘氫發電

- + Wet Scrubber

- + Wet-EP

- + VOC Catalys

- + VOC Condenser

- + 緊急應變設備

- + N2防逆火

|

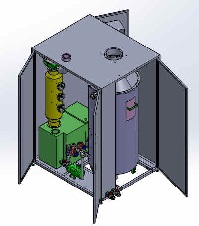

Scrubber Model

|

VOC-3000

|

|

Dimensions (mm) |

1500W x 1250D x 2200H(mm) |

|

Weight (kg) |

110 |

|

Life time |

1 year |

|

Total Flow Rate (LPM) |

3000 LPM |

|

Inlet ports |

9” Flange |

|

Outlet port |

4” Flange |

|

DRE

|

<2000PPM=90%

>2000PPM=95%

|

Abatement method :Thermal Dry (VOC catalyst)

Max. abatement airflow(Capacity) :10~12m3/min

Process:Abatement of most VOC gases, including IPA, acetone, and organic amines

VOC catalyst perfectly removes VOCs and odors emitted from painting, printing, enamel coating, film factories and chemical plant, etc.

Basic Principle:

Ceramic

support coated with precious metals (Pt, Pd, etc) efficiently removes VOCs at low temperature range of 200~400℃Catalyst

CxHyOz + O2 ----> H2O + CO2

200~400℃Direct firing

CxHyOz + O2 ----> H2O + CO2

700~900℃

Material:

Support : Cordierite Pt, Pd, chemical element, etc.

IPI Catalysts

has long been a leader in the development of highly active, robust and

...ive catalysts and related technologies for the destruction of volatile

organic compounds (VOC). While there are a number of methods to abate VOC

emissions, catalytic incineration has become a leading choice because it can be

more versatile and economical that other approaches. Our VOC catalysts control emissions

of hydrocarbons (HCs) and other VOC from a wide

variety of industrial processes, including chemical processes, paint systems,

food processing, printing, electronics, and soil and groundwater cleanup

systems. They help customers meet increasingly stringent emissions standards

reliably and cost-effectively.

Applications:

• Purified Terephthalic Acid (PTA) process

• Acrylic Acid

• Phthalic Anhydride / Maleic Anhydride

• Acrylonitrile

• Styrene

• Phenol / Acetone

• Formaldehyde

• Ethylene Oxide / Ethylene Glycol

• Petrochemical

• Rubber

• Printing

• Chemical plant

• Wire enamel coating

• Painting factory (Automobile, home appliances, etc.)

• Painting factory (Off-set, gravure)

• Aluminium and Film coater

• Food factory

• Waste food disposer, livestock feces disposer, waste water disposal plant, etc.

Advantage:

• We developed local thermal/dry (catalyst) type VOC abatement system as a way to reduce VOC emissions from semiconductor manufacturing processes.

• Local scrubber design lowers initial and running costs.

• Delivers a high abatement rate at low power consumption.

• Space-saving footprint : Attaining the smallest footprint for VOC abatement solutions.

• Original,high-efficiency heat-exchanger

• Neat & compact

• Cost efficient

• Ease of operation and maintenance

• IPI catalysts convert hydrocarbons (HC) and volatile organic compounds (VOC) into carbon dioxide and water.

• IPI catalysts remove hydrocarbons (HC) and volatile organic compounds (VOC)

• They are exceptionally efficient and durable, which can lead to lower operating costs than other technologies.

• IPI catalysts can provide higher activity, stability and ...ivity to meet demanding requirements

• Wider application of catalysts to the oxidation of volatile organic compounds (VOCs) has placed new requirements on catalysts. Some of these requirements are oxidation of VOCs at lower temperatures and oxidation of gas streams with more and varied VOCs.

• Most IPI catalysts are supported on ceramic honeycomb and all products feature

• Suited for the manufacturing process of highly dielectric and strong dielectric thin films.

• Safely removes VOC (such as THF and butyl acetate), Pb, Zr, Ti and other DPM, and organo-metallic complexes by oxidization.

• Allows the full oxidization at the air-mixing ratio equal to or lower than the lower explosive limit of organic solvent at a temperature range exceeding250℃with the aid of the action of an oxidizing catalyst.

• Eliminates the need for propane and other combustion fuels for the heater heating system, thereby reducing the emissions of CO2.

• Prevents the emission of produced metallic oxides to outside the system, by the installation of filters.

• Ensures safety through monitoring of pressures and temperatures.

• Long durability

• Low pressure ...

• Compact sized unit is available due to low pressure ... honeycomb

• High stability at high temperature Excellent thermal shock resistance

• 使用電熱式可處理有機廢氣的種類多

• 無需燃料配管,初設成本低廉

• 與觸媒結合使用,實現更低運行成本

• 使用電能,操作簡單,安全可靠

• 設備超小型化,可隨地設置

• 可直接設置於潔淨室

• 同樣設計的大型設備也能製作

• 適用風量:1~10M3/Min